- #Cnc router machine drivers

- #Cnc router machine driver

- #Cnc router machine upgrade

- #Cnc router machine full

$4=1 (step enable invert, bool)(Board V1, V2, V3 Matte = $4=0 - Glossy board V3 = $4=1)Īgain, experiment with these settings to find the best set up for your machine.Īs you build a machine you learn areas that could be improved upon, and so below are a few mods and upgrades we have added to the OX build with more to come!

OX CNC GRBL Settings - This information can also be used to set up other firmware as well

#Cnc router machine upgrade

I have plans to upgrade this soon to a 8mm *4 lead soon.Įxperiment with these settings to find the best set up for your machine. Its suited more for high speed movement of a short run, but its what I had and its working.

Please note: The acme threaded rod that I am using (in the video) is pretty unique and really should not be used for this application.

#Cnc router machine full

#Cnc router machine drivers

For instance if you are using MXL belt or more/less teeth on your pulley, different ACME lead screw or how many steps your drivers are set to drive your steppers at. Your setting may/will differ depending on your setup.

#Cnc router machine driver

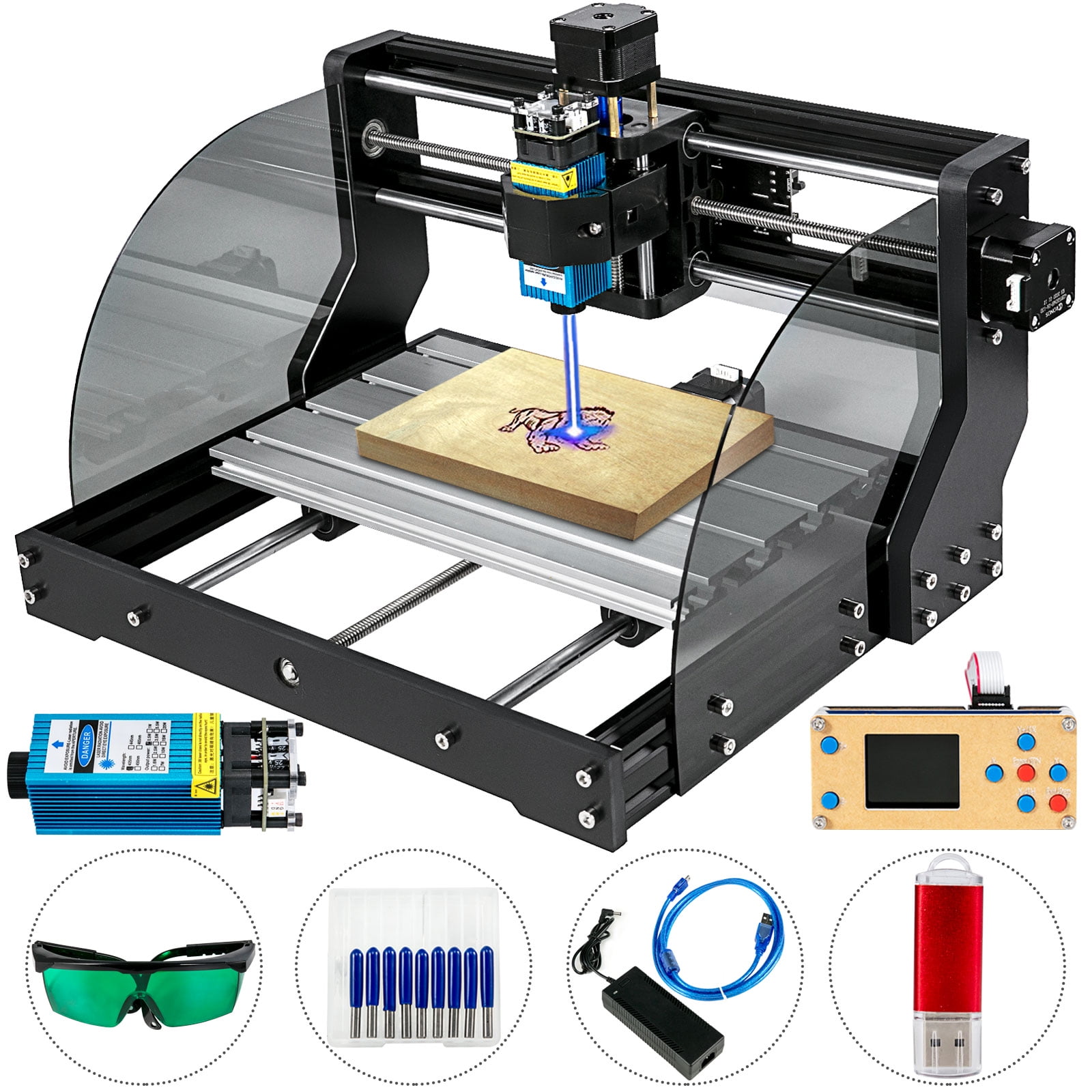

There are many different driver packages that can be usedīlackBox CNC Controller and the INTERFACE Pendant Installing Arduino and GRBLShield into the electronics enclosure (complete with fan) - 10:58-19:45.Installing the belts for Y-movement - 0:09-10:58.Adding the missing corner brackets to the back of the main gantry rails - 1:21:25-1:23:32.Inserting the center table support - 1:16:47-1:21:25.Inserting Y-rails into the gantry and attaching the front and back table supports - 1:07:19-1:16:47.Attaching 20x40 circuit-board cross-brace to the gantry - 1:03:42-1:07:19.Attaching corner brackets to gantry assembly and final adjustment of X-axis movement - 59:24-1:03:42.Mounting the gantry assemblies to frame - 49:40-59:24.Tapping ends of frame rails - 46:56-49:40.Installing the motor into X/Z-axis assembly - 45:36-46:56.Final fastening of Z-axis ACME rod - 38:10-45:36.Assembling the Z-axis assembly from the motor assembly and the gantry assembly - 36:28-38:10.Initial insertion of Z-axis ACME rod - 35:45-36:28.Fastening Z-axis motor assembly to 20圆0 rail - 34:32-35:45.Installing ACME block on X/Z-axis assemblies - 30:48-31:38.Initial adjustment of X/Z-axis assembly eccentrics to fit 20圆0 rail - 28:20-30:48.Adjusting gantry assembly eccentrics to fit 20x80 rail - 9:14-11:28.Adding motor to the gantry assemblies - 6:00-9:14.Assembling the gantry plates and wheels - 1:25-6:00.Much thanks to member Rural for putting these indexes together to make building the OX even easier These are indexes into the OX assembly videos: On an interesting side note - the ROUTY was used to cut the plates needed for the OX, so its machines making machines! I been learning a lot from the upgrades the guys on the forums have been working up ( props go out to them) and wanted to incorporate them into a V-Slot machine, so the OX was born. The OX design is largely based on the ROUTY which is based on the Shapeoko cnc machine. 'It's going to be a fun build that we are filming from the start to the finish so that anyone can follow along and build as well.' 1' x 1.5' (310 x 480) to a large format OX that can cut approx. There are a lot of cool features this machine has but one of my favorites is that it can be built in a small format that will cut approx. To be honest, I was going to wait before I released but I could not hold it back any longer It's going to be a great machine for our shop! It has been taking me some time because I am working on a build-along video as well as sourcing parts needed to complete the build. I have been working on a new CNC machine build I call the OX ( because its strong )

0 kommentar(er)

0 kommentar(er)